Energy Hunter - HVAC and Utilities

- Home

- Energy Hunter

Sustainability helps a company’s profitable growth, through energy efficiency, heat recovery, reduced fuel bills, reduced CO2 emissions, savings in maintenance costs, and has a positive impact on the environment. With rapidly, increasing energy costs, plant managers have more and more pressure for their contribution to sustainability. Major equipment installed in food, beverage, manufacturing, and HVAC industries consume high amounts of energy, be it by burning natural resources such as carbon fuels or electricity, which are generated with the same.

The series of '10 Energy Hunter applications' from Alfa Laval, offers real-life application examples on how gasketed plate heat exchangers can help companies with sustainability targets, on the way to a better planet. These applications have been compiled from many successful Alfa Laval distributor partners who are already using their knowhow built over the years, to help their customers reach their sustainability targets.

These global best practices have been investigated and the knowhow compiled, in order to help more Alfa Laval partners to offer these proven sustainability solutions, with Alfa Laval GPHE’s. Sustainable savings are found around major plant equipment, associated with GPHE’s be it in the manufacturing industry, HVAC or process utilities.

Energy Hunter in HVAC and Manufacturing industries, Utilities applications

Booklet (including all 10 applications)

-

Savings in electricity

-

Savings in fuel costs

-

Savings with efficiency and uptime

Chiller condenser protection

The condenser of a chiller using open cooling tower water is prone to develop a layer of CaCO3.

Rule of thumb in the industry is that a 1 mm coating of CaCO3 inside the tubes, can mean 3°C higher condensation temperature of the refrigerant gas at the condenser.

This equates to approximately 10% higher condensation pressure and higher electricity consumption of the compressor.

Heat recovery from warm waste water

With Alfa Laval wide gap plate technology, heat recovery is efficient at the same time blockage free for wastewater containing < 5 mm particles or fibres.

Wastewater temperatures as low as 35°C and as low 10 m³ per hour can save 175 kilowatts (150,000 kCal/hr) with a payback period of less than six months, preheating the boiler feed water to 30°C.

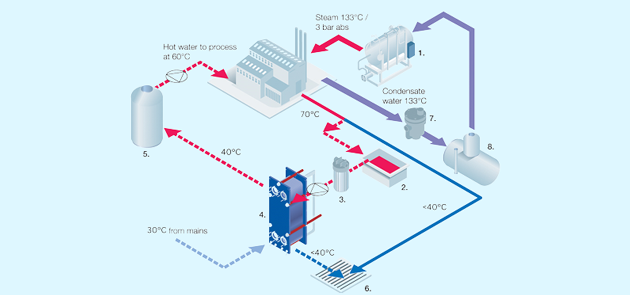

Energy Hunter – HVAC - AHRI performance certification

Can you accurately measure 0.5°C? What happens to the operation of the chiller if the installed pressure breaker gasketed plate heat exchanger under performs by 0.5 °C?

Lower evaporation temperatures lead to higher lift with the chiller compressor and increasing electricity consumption of up to 3%. Installing Performance Certified gasketed plate heat exchangers provides a payback period of under three years.

Energy Hunter – HVAC - Free cooling with chiller bypass

A chiller is one of the highest running cost equipment in many plants. Those with a water-cooled condenser can win in two ways with an Alfa Laval gasketed plate heat exchanger.

One to protect the chiller from CaCO3 coating on the tubes, saving electricity with lower condensing temperature and pressure and the other is by turning the chiller off up to 30 days per year, depending on the geographic location and the wet-bulb temperature.

AHRI Performance Certification is vital as approach temperatures of 1°C are needed and who can measure 0.5°C!

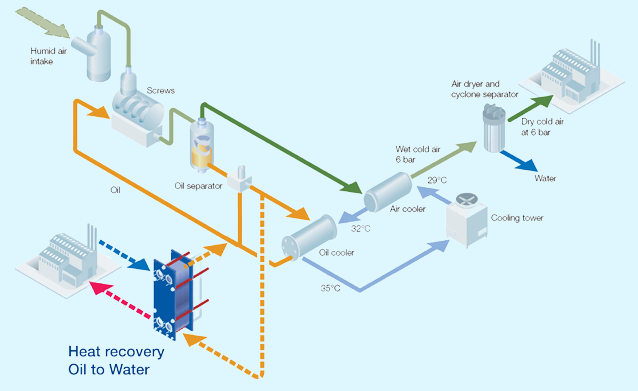

Heat recovery from air compressors

72% is the conversion of electricity to waste heat with air compressors. Compressed air and lubricating oil are often cooled with in built heat exchangers, releasing the heat to the atmosphere.

Cooling the air also helps the dryer run effectively, reducing moisture content for critical air equipment.

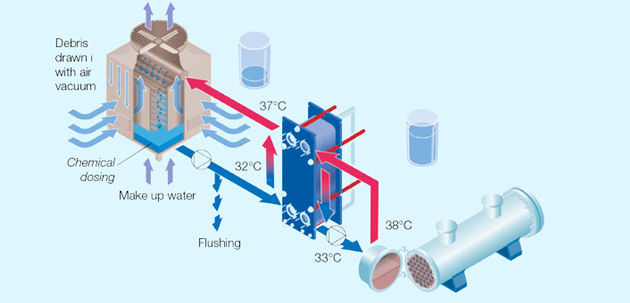

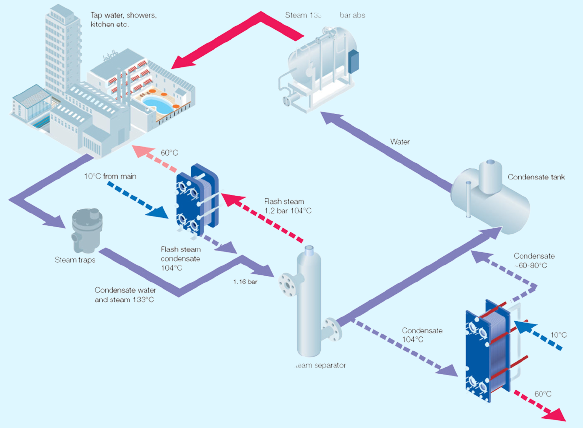

Heat recovery from waste flash steam

All industries using steam as a heat source have problems with steam management.

With a simple cyclone separator at the condensate collection point, flash steam can be condensed, heating water up to 80°C.

Recovering 500 kg per hour of flash steam can save up to 5,000 Euro per month. The return on investment is less than 3-6 months.

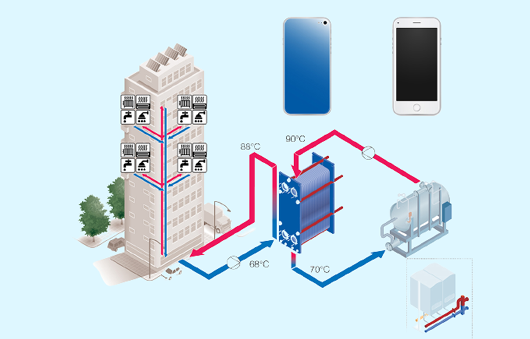

Boiler protection

Especially for retrofit applications, the building circuit can contain debris, mud, CaCO3 and oxygenated water.

The CaCO3 can bake at 300°C plus fuel temperatures and with thermal expansion/contraction crack the boiler’s heater.

Two identical buildings located side by side, one with gasketed plate heat exchanger protection and the other without, has fuel costs 30% less, as with protection, the boiler heater does not have a coating of CaCO3.

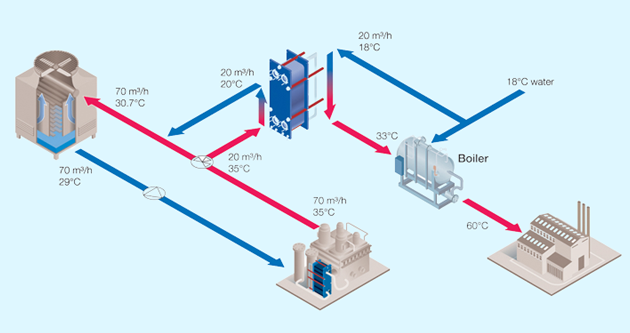

Heat recovery from open cooling tower

This is exceptionally beneficial where heating and cooling takes place at the same plant.

Typically for preheating boiler feed water close as 2°C to cooling tower return.

Savings are in increased cooling tower capacity, less fuel costs for boiler operation (almost half) and less evaporation of water at the tower, hence saving water.

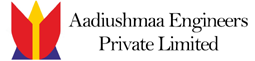

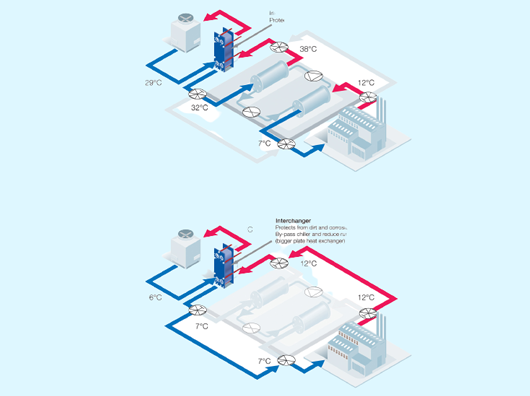

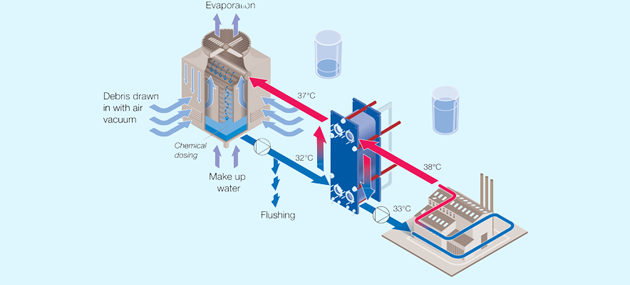

Cooling tower interchanger

Plant cooling equipment protection from open cooling tower mineral deposits CaCO3 and Chloride ions, minimum fouling from debris.

Savings are in maintenance-free operation of plant equipment, lower pumping costs avoiding pipe diameter reduction and replacement of corroded equipment.

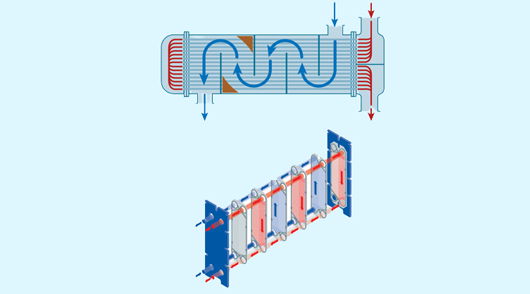

Shell-and-tube replacement

Based on the right channel type of gasketed plate heat exchanger and proportional heat surface area.

Savings are with less footprint -

including removal space for tube bundle, less hold up volume hence faster response times, easier and quicker maintenance and heat losses to the atmosphere from the shell-and-tube surface.

Get A Quote

Partners in Progress: Our Key Collaborators