Choose Suppliers Associated with the Best Heat Exchanger Manufacturers in India, Alfa Laval

- Home

- Heat Exchanger Manufacturer

Leading Stainless Steel Heat Exchanger Manufacturers Fuels the Services Provided by Aadiushmaa

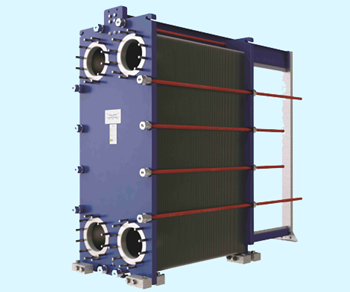

Heat exchangers are devices that transfer heat between two fluids. Industrial heat exchanger manufacturer in India understand the importance of delivering high-quality products that are durable and efficient. Our stainless steel heat exchanger manufacturers, Alfa Laval designed it to withstand harsh conditions and deliver optimal performance. Made with high-grade stainless steel, our heat exchangers are corrosion-resistant, ensuring longevity and reliability.

Product Detail

| Plate Type | Brazed, Gasketed, Semi-Welded , Welded |

| Field gaskets | HNBR,NBRP,NBR,EPDM,EPDMP Special MOC on request |

| Plate Material | SS316, Alloy C-276, titanium and many more |

| Frame and pressure plate | Carbon steel, epoxy painted and |

We are plate heat exchanger suppliers in India that provide cost-effective and efficient solutions for heat transfer. These heat exchangers are ideal for applications that require high heat transfer coefficients, low-pressure drops, and low fouling. At our company, we specialise in designing and manufacturing plate heat exchangers that are customised to meet the specific needs of our clients. Our plate heat exchangers are used in various industries, including chemical, pharmaceutical, food and beverage, and HVAC.

How does a Heat Exchanger Work?

Heat exchangers are instruments designed to transfer heat between two or more fluids using arrangements of metallic plates. This is done without letting them come in contact with each other. They have a major role in multiple industries, including HVAC systems and refrigeration units. The basic principle behind heat exchangers is the continuous exchange of thermal energy. This technique of heat exchange is much more effective when compared to a conventional heat exchanger as in this technique, the fluids are exposed to a significantly greater area as they get spread over the metal plates.

- Quenching oil cooling

- Induction furnace cooling

- HF welder cooling

- Plastic molding cooling

- Oil separator

- Roll cooling in hot and cold rolling mills

- Hydraulic press machine cooling

- Transformer oil cooling

- Acid- Sulphuric, Nitric, and any other

- Refrigeration- Ammonia Condenser, Cold Storage, Ice plant etc

- Chemical Cooling/Heating

Benefits of Choosing Us as Heat Exchangers Manufacturers in India

Efficient Heat Transfer

Allows for efficient transfer of heat energy from one medium to another, resulting in lower energy costs.

Cost Savings

Reduces operating costs by improving efficiency, decreasing maintenance requirements, and extending equipment life.

Improved Product Quality

Heat exchangers help maintain a consistent temperature, reducing the risk of product spoilage and improving quality.

Environmentally Friendly

Our heat exchangers Increase energy efficiency and reduce carbon footprint, leading to a greener environment.

Why should you Choose Aadiushmaa?

Having been in business since 1999, Aadiushmaa Engineers Pvt. Ltd has gained immense popularity as a trader and distributor of a wide selection of plate heat exchangers. We pledge to uphold our commitment to our clients by making every attempt to meet their needs and their expectations. Our team of experienced engineers and technicians use smart technology and high-quality materials to design and manufacture heat exchangers that are efficient, reliable, and durable.

With our commitment to quality and customer satisfaction, you can trust us to deliver the best heat exchangers for your applications. We have created a well-equipped warehouse with all the latest amenities for keeping a wide variety of products. Our buying process is strictly regulated by our qualified team of experts.

Got a Question? We've the Answer!

How many types of Plate Heat Exchangers are available in our company?

You can find four types of Plate Heat Exchangers with us. They are- Gasketed Plate heat exchangers, Brazed Plate heat exchangers, Semi-Welded plate heat exchangers, and Welded Plate heat exchangers.

What is the range of the pressure that a Plate Heat Exchanger (PHE) can handle?

The range of pressure a Plate Heat Exchanger can handle is from 1kg to 50kg.

What is the maximum temperature reach of a heat exchanger?

The maximum temperature reach of a heat exchanger is from 30 Degrees to 200 Degrees.

Can you update us about the MOC (material of construction)?

Yes. Generally, plates are SS-316, but we can provide Hastelloy, Titanium, and others also depending on the liquid that will flow through it. Gaskets like NBR, EPDM, and Viton are provided. The Main frame is made up of cast iron or powder coating.

What is the use of a Plate Heat Exchanger?

A Plate Heat Exchanger is used to transfer heat between two fluids through thin metal plates. For example, for water and steam – to heat the water, for oil and water – to cool the hot oil, for Oil and Oil – to cool the hot oil and pre-heating the oil to be heated, and acid and water – help to maintain the temperature of acid.

What application does a Plate Heat Exchanger handle?

Applications a Plate Heat Exchanger can handle are as follows:

- Quenching oil

- Water Quenching

- Induction furnace

- Induction Hardening

- High-Frequency welder

- Refrigeration – Ammonia chilling plants

- HVAC (Humidity ventilation air conditioning)

- Process cooling – chiller water and machinery

- Forging Hammer-oil cooling

- Electrical chiller protection

- Air compressor for oil cooling

- Water vs Water

- Dgset oil cooling

- Waste effluent from plants

Do you provide servicing for Plate Heat Exchangers?

Yes, we provide service engineers at the working site and also deliver the spare parts as per one's requirement.

Can we order the Plate Heat Exchanger as per our requirements?

Yes, you can order the Plate Heat Exchanger as per our requirements. We need

Both side media details – viscosity, specific gravity, Side -1 – flow/temp in and out / pressure drop (if specific)

Side -2 – flow/temp in and out / pressure drop (if specific)

What is the delivery period of a Plate Heat Exchanger?

The delivery period depends on different models of PHE. Generally, it takes 1 to 2 weeks to deliver the BPHE, 1 to 2 weeks for the 5’’ line size standard version, and 6 to 8 weeks for the 6’’ to 8’’ line size standard version. The delivery period for a non-standard version of any size may vary according to the specifications.

What guarantee does Aadiushmaa give us for their Plate Heat Exchanger?

Aadiushmaa, plate heat exchanger suppliers gives a one-year warranty against any manufacturing defects.

Can we get the design of the Plate Heat Exchanger equivalent to the shell and tube?

Yes, you can get the design of a Plate Heat Exchanger equivalent to a shell, and tube and it will work more efficiently.

Can liquid particles flow through the Plate Heat Exchanger?

Yes, we can design specific sizes of Plate Heat Exchanger to pass the particles.

How much time is needed to install a Plate Heat Exchanger?

The time needed to install a Plate Heat Exchanger depends on the model of PHE and customer requirements.

How is a plate and gasket exchanger dismantled?

Plate and gasket exchangers are dismantled manually with the help of engineers.

Do Plate Heat Exchangers need servicing?

Yes, the Plate Heat Exchangers need servicing.

How can I get a quote?

Our officials require some special details in order to provide a quote. The details are the name of the fluid: primary and secondary, type of industry, Inlet temperature, outlet temperature, chemical, temperature, working pressure and flow.

Client Feedback

We have been using heat exchangers from this manufacturer for years, and we are extremely satisfied with their quality and performance.

- Dinesh Agarwal, Chemical and Petrochemical Industry -

Their plate heat exchangers are compact, efficient, and easy to maintain. Highly recommended!

- Pratyush Singh, Oil and Gas Industry -

We needed a customised solution for our specific application, and this manufacturer delivered exactly what we needed.

- Rishi Jaiswal, Food and Beverage Industry -

Their heat exchangers are made from the finest stainless steel, ensuring durability and long-lasting performance.

- Prachi Gupta, Pharmaceutical Industry -

Aadiushmaa’s heat exchangers are cost-effective and deliver reliable results. We couldn't be happier with our purchase.

- Adarsh Gupta, Power Generation Industry -

Their corrugated tube heat exchangers are perfect for our application, and we appreciate the expert advice and support they provided throughout the process.

- Aditya Sharma, Automobile Industry -

Their customer service is outstanding, and they are always willing to go above and beyond to ensure customer satisfaction.

- Aditi Mehta, Pulp and Paper Industry -

We have tried other heat exchangers in the past, but these are by far the best we've ever used. Highly recommended!

- Chirag Desai, Marine Industry -

Get A Quote

Top Manifold Options from Leading Stainless Steel Heat Exchanger Manufacturers

Heat exchangers come in various types, each designed to suit specific applications. Stainless steel heat exchanger manufacturers like Alfa Laval offer three common types of heat exchanges are described below.

Shell and Tube Heat Exchangers:

This is the most widely used type of heat exchanger and consists of a shell and a bundle of tubes. The fluid to be cooled or heated flows through the tubes, while the cooling or heating fluid flows through the shell.

Plate Heat Exchangers

This type of heat exchanger consists of a series of plates with corrugations that create a larger surface area for better heat transfer. The fluids flow through alternate channels between the plates.

Finned Tube Heat Exchangers:

This type of heat exchanger is used for applications where the temperature difference between the fluids is low. The tubes are fitted with fins that increase the surface area for better heat transfer.

Best Heat Exchanger Manufacturers in India, Transforming Operations

Industrial heat exchangers are used in a wide range of applications, including power generation, chemical processing, and refrigeration. As a result, it is essential to choose a reliable industrial heat exchanger manufacturer and supplier that can deliver high-quality products that meet your specific requirements. Leading industrial heat exchanger manufacturer in India provides high-quality heat exchangers to various industries. With years of experience in the industry, Aadiushmaa Engineers have built a reputation for delivering innovative solutions that meet the most demanding requirements. Their team of engineers and technicians work closely with customers to design, manufacture and deliver custom heat exchangers that are reliable, efficient, and cost-effective.

Heat Exchanger Manufacturers are Needed in Which Industries?

Our shell and tube heat exchanger manufacturers in India, Alfa Laval play a crucial role in various industrial sectors such as chemical, petrochemical, power generation, and HVAC systems. Heat exchangers are used for transferring heat energy from one medium to another; thus, their role is vital in the functioning of industrial processes. Heat exchanger companies in India have been producing a diverse range of products to cater to the needs of different industries. From shell and tube heat exchangers to plate heat exchangers, numerous types of heat exchangers are available in the market. Manufacturers fabricate these heat exchangers using materials like stainless steel, copper, and aluminium.

Partners in Progress: Our Key Collaborators