Unleash Cooling Excellence with the Premium Vapour Absorption Machine service provider - Aadiushmaa

- Home

- Vapour Absorption Machine

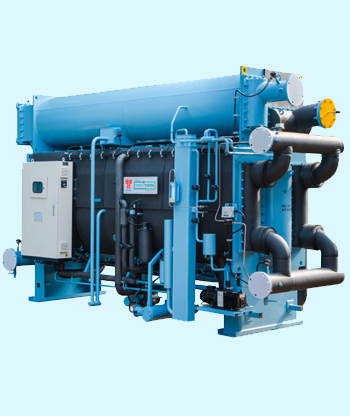

Vapour Absorption Machine

What is a Vapour Absorption Machine, And How does it Work?

A vapour absorption machine, commonly known as a vapour absorption chiller, is a device that utilises a heat source to produce cooling effects without requiring mechanical compression. It operates based on the principle of absorption refrigeration. The primary components of a vapour absorption machine are a generator, a condenser, an absorber, and an evaporator.

The process begins with the generator, where a heat source, like steam or hot water, provides energy. This energy separates the refrigerant from the absorbent. The refrigerant vapour then flows to the condenser. Here, it is cooled and condensed into a liquid state.

Product Detail

| Capacity | 10 to 3500 tr |

|---|---|

| Working Material | DM Water (Demineralized water), Lithium bromide (LiBr) |

| Temperature | 1 deg – upto as per requirement |

| Operated | Steam Fired, Direct fired, Gas/ Diesel |

Next, the liquid refrigerant enters the evaporator, where it absorbs heat from the surroundings. This causes the evaporation of the refrigerant. This evaporation process extracts heat, resulting in a cooling effect. Finally, the refrigerant vapour is directed to the absorber, where it is absorbed by the absorbent, completing the cycle. By utilising heat instead of mechanical compression, VAM machines offer a more energy-efficient and environmentally friendly alternative for cooling applications.

Working Principle of a Vapour Absorption Chiller

The working principle of a vapour absorption chiller revolves around the cycle of absorbing and releasing the vaporous refrigerant. In a vapour absorption chiller, the refrigeration process begins with the evaporation of a refrigerant, typically ammonia or lithium bromide. The evaporated refrigerant is then absorbed by an absorbent, creating a refrigerant-absorbent mixture. The mixture is then pumped into a generator, where it is heated using an external heat source. This heat causes the refrigerant to vaporise and separate from the absorbent, forming a high-pressure, high-temperature vapour. The vapour is then directed to a condenser, where it is cooled and condensed back into a liquid state, releasing the absorbed heat.

The high-pressure liquid refrigerant then passes through an expansion valve, where its pressure and temperature decrease. This low-pressure, low-temperature refrigerant is then circulated through an evaporator, where it absorbs heat from the surroundings, creating a cooling effect.

The absorbent, which now contains a lower concentration of refrigerant, returns to the absorber, where it is ready to absorb more evaporated refrigerant, continuing the cycle. This process is driven by the heat input, making vapour absorption chillers suitable for applications where waste heat or renewable energy sources can be utilised efficiently.

Get A Quote

Service of Vapour Absorption Chiller

Our service for VAM machines offers outstanding features. We collaborate only with the best vapour absorption machine manufacturers in India, Thermax Global, to provide superior services. It can achieve temperatures as low as 1 degree C when using pure water and maintain deltas of up to 30 degrees C. The flow cycle is leak-proof, minimising the risk of corrosion. We are vapour absorption machine suppliers who provide a design that ensures zero crystallisation, maximising performance. You have the option to choose one or multiple fuel-driven machines based on your convenience. Moreover, we provide specialised, high-quality parts to ensure reliable operation.

Availability of Spare Parts

If your vapor absorption machine requires spare parts, we are here to assist you. Our inventory includes all the necessary components to ensure the smooth operation and maintenance of your unit. Vapor absorption machines are gaining popularity due to their exceptional efficiency and minimal environmental impact, and we are committed to supporting your chiller's longevity and performance through our spare part availability.

Partners in Progress: Our Key Collaborators